High-quality products, superb technology

HOT PRODUCTS

ABOUT OUR COMPANY

ABOUT US

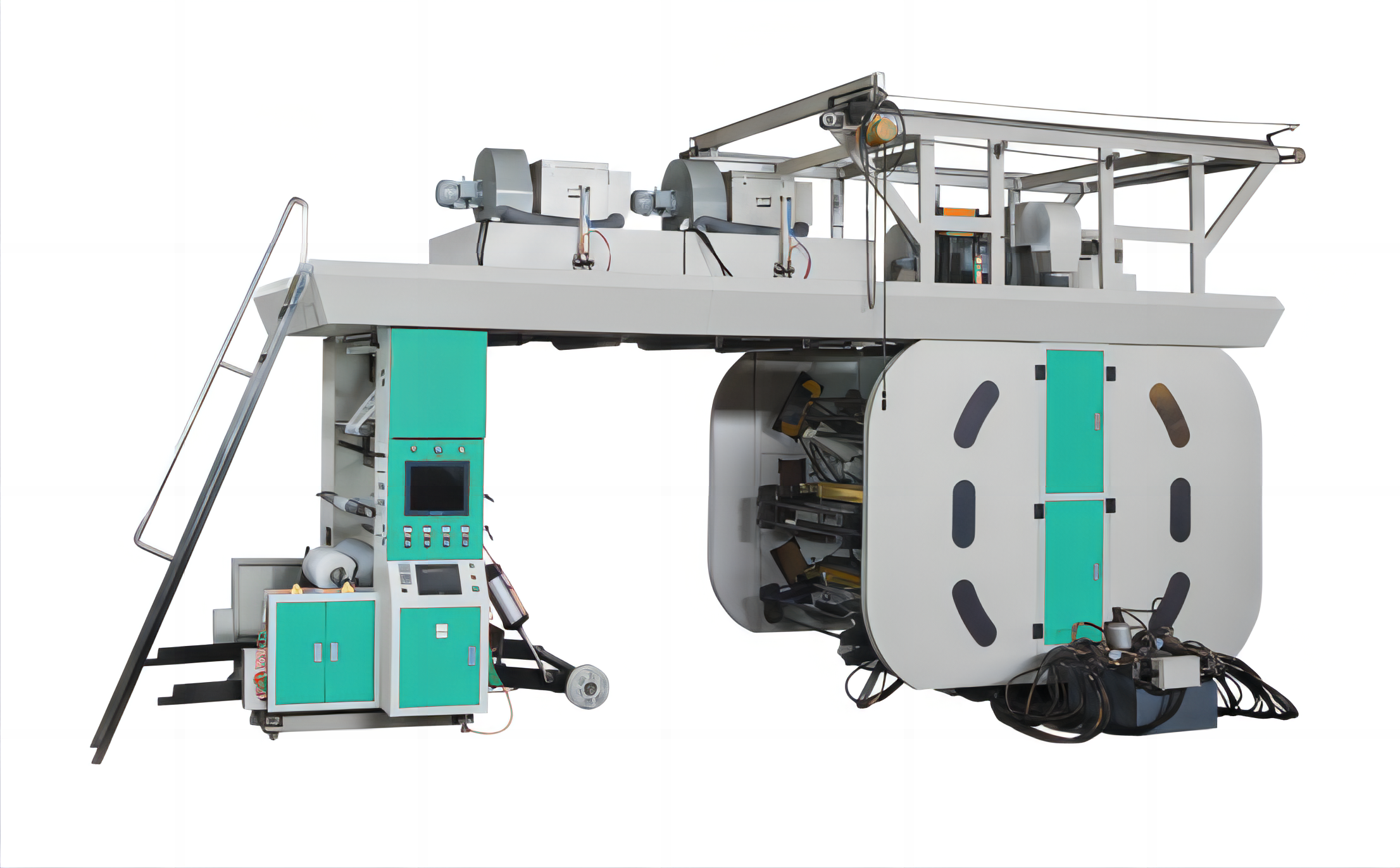

- CI Flexo Printing Machine

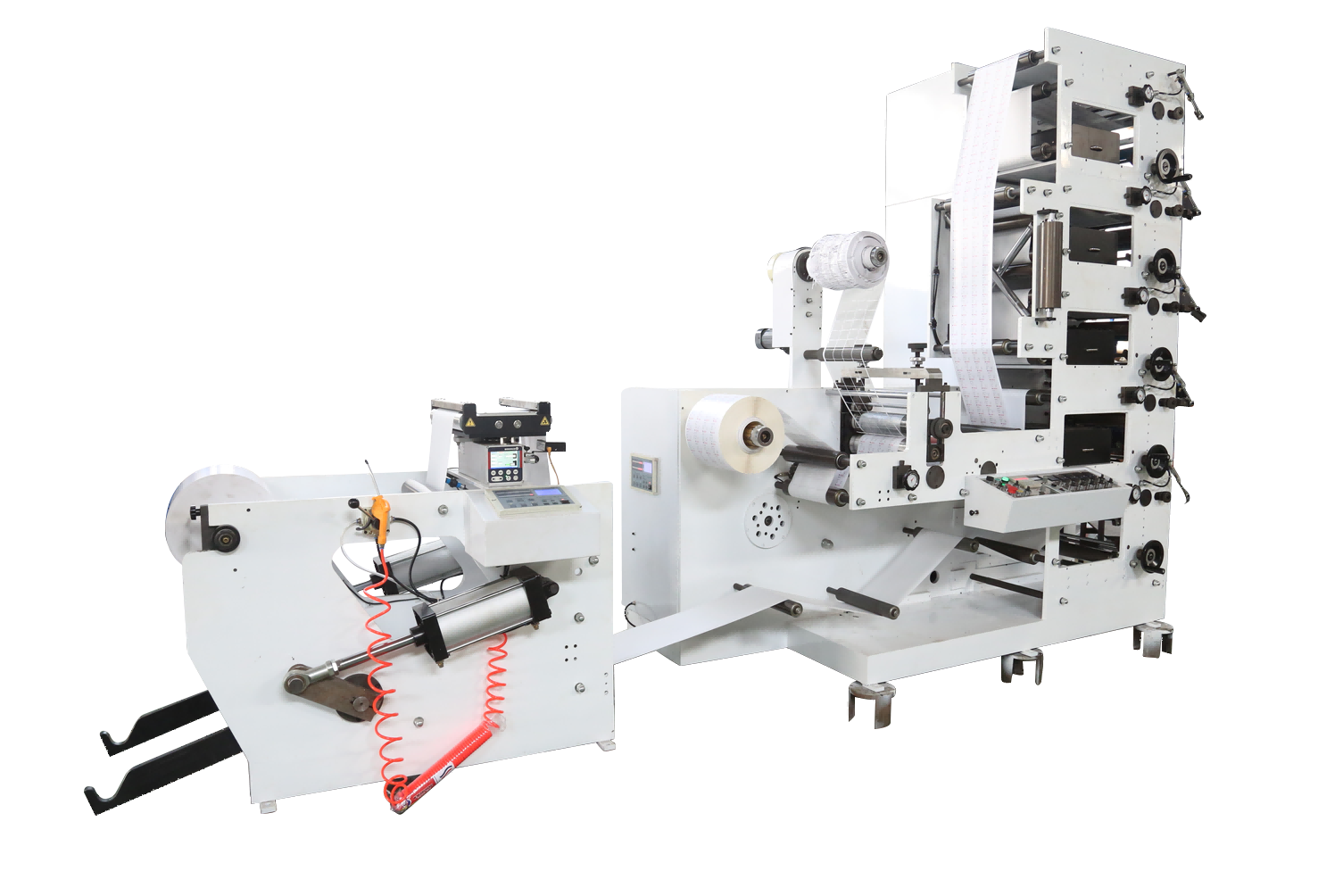

- Stack Flexo printing machine

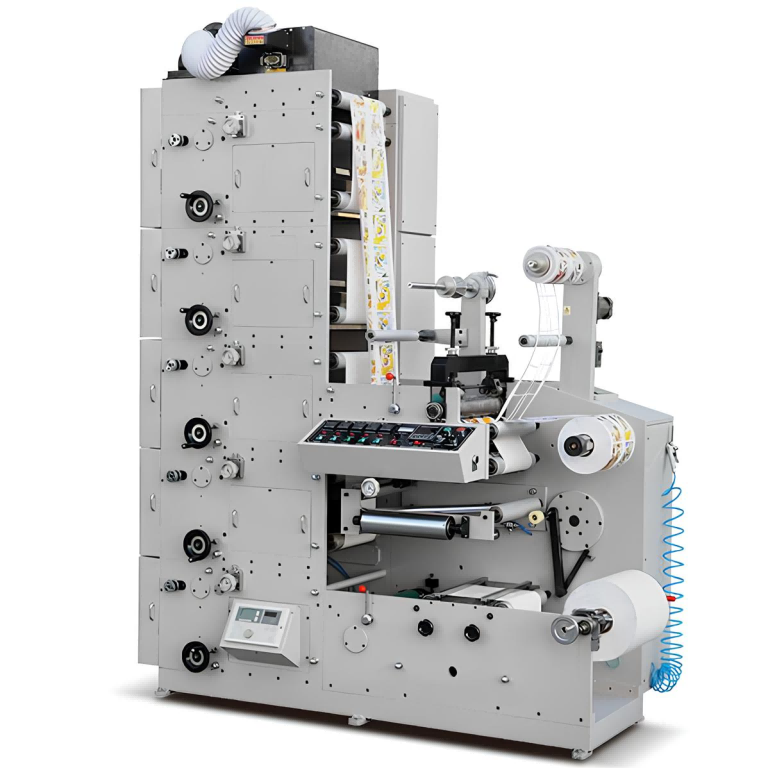

- Label Flexo printing Machine

We can provide the best service for our customers

Latest News

Narrow web inline flexo press - the best printing machine for self-adhesive label

Summary Self-adhesive label printing, also called self-adhesive printing and trademark printing, uses a certain printing method to print sticker paper into self-adhesive materials. The printed products can be peeled off and pasted on goods or packaging. Mark it on the object. The label printing industry has achieved rapid growth with the development of the market economy, especially the rapid development of daily chemicals, food, detergents, medicine, cosmetics, home appliances and small household appliances, supermarkets, logistics and other industries. After several years of development, the label printing industry has achieved rapid growth. The printing industry chain has been formed around the world. As a recognized green printing method, flexo printing uses ink and UV ink and has low environmental pollution. Its advantages are simple machine structure, low cost, printing quality that is almost comparable to offset printing and gravure printing, and it has the characteristics of thicker ink layer than offset printing products. Among them, the narrow web inline flexo printing machine is the most suitable for printing self-adhesive trademarks. Main characters of inline flexo printing machine 1. The distance from the unwind to rewind is short. 2. each printing unit directly drive by servo motor, high stability. 3. doctor blade with ceramic anilox roller transfer ink, ink volume stable. 4. Machine use servo motor control automatic registration system, color register accuracy is high. 5. mainly use Water-based ink (UV ink) to printing, pollution-free, environmentally friendly, printing speed varies according to the network 6. machine actuall printing speed reach 150 meter per min 7. main application: Printing bills, labels, cardboard, […]

Read More

What is stack flexo printing machine?

Summary The stack flexo printing machine is one of the three types of flexo printing machines. Flexo printing is a recognized green printing method. It emits less when printing with ink and has no pollution to the environment. In addition to conventional paper and PVC, the substrates for flexo printing are Corrugated paper, film and other materials can also be printed. Therefore, flexo printing is widely used in food packaging and pharmaceutical packaging. The stacked machine has a simple structure and a lower price than the other two types. It has the largest market share. Structure of Flexo printing machine The printing color groups of the stacked flexographic printing machine are stacked up and down and arranged on one or both sides of the main wall panel of the printing component. Each printing color group is driven by a gear mounted on the main wall panel. During printing, the substrate passes through each printing group in sequence to complete all printing. Each printing color group has an impression cylinder, a plate cylinder and an ink transfer device, and the structure of each printing color group is the same. The laminated flexographic printing machine can print 1 to 8 colors, but most of them are 6 colors. If equipped with a flipping device, it can also print on the front and back sides.

Read More

What is CI ( central impression) flexo printing machine?

Summary CI flexographic printing press, also known as central drum flexographic printing press. Each printing unit surrounds a Central impression cylinder. The printing material is wrapped around a common impression drum for registration printing. Because the gears are directly driven, whether it is paper or film, even if no special control device is installed, it can still be overprinted very accurately, and the printing process is stable. It is often used to print color products. Some people have predicted that CI flexo printing will be the new mainstream of flexo printing in the 21st century. Structure of CI Flexo printing machine The CI flexographic printing machine is mainly composed of 4 parts, namely, the unwinding and feeding parts, the printing parts, the drying parts and the rewinding and rewinding parts. In addition, there are generally measurement and control devices such as tension control, edge control, registration control, and print observation, as well as mechanical status monitoring and fault diagnosis systems. Since the material is tightly wrapped on the central impression drum, the tension of the material is very stable, and the machine's registration accuracy is very high, which can reach ±0.1mm. This color registration accuracy is significantly better than the other two types of flexo printing machines. At the same time, the CI flexo printing machine occupies less space than the gravure printing machine, has lower requirements for site personnel, uses solvent inks and water-based inks, and is environmentally friendly and causes less environmental pollution. There is a worldwide trend of flexo printing replacing gravure printing. It should be […]

Read More