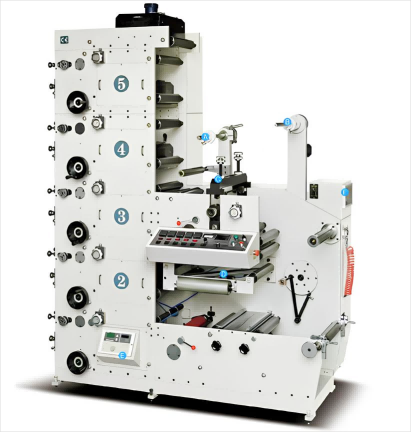

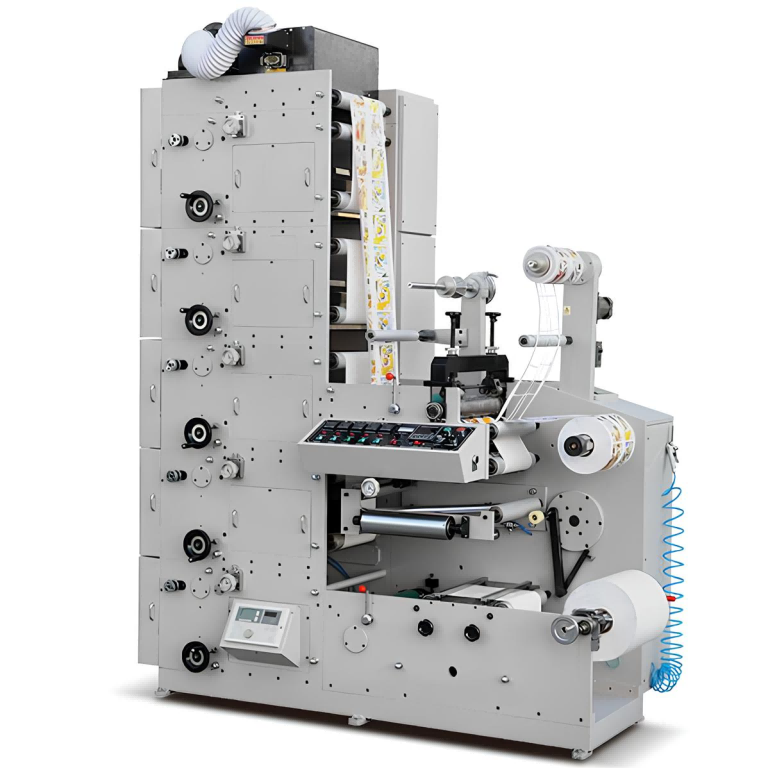

The 4 color flexo printing machine is specially designed for paper material, it uses single doctor blade with ceramic anilox roller transfer ink, surface friction rewinding, max printing speed reach 120 meter/min. 360-degree longitudinal adjustment of color registration accuracy, printing accuracy can reach ±0.2mm. Equipped with infrared drying, fast drying after printing. The machine has a compact structure, a small footprint, and a relatively low price. It is an efficient and economical flexo printing machine for printing paper cups and paper straws.

Parameter

| TECHNICAL SPECIFICATIONS | ||||

| Model | YTA-800 | YTA4-1000E | YTA4-1200E | YTA4-1400E |

| Max. Material Width | 800mm | 1000mm | 1200mm | 1400mm |

| Max. Printing Width | 760mm | 960mm | 1160mm | 1360mm |

| Max. Machine Speed | 130m/min | |||

| Printing Speed | 120m/min | |||

| Max. Unwind/Rewind Dia. | φ1200mm | |||

| Machine drive structure | Gear and belt drive. | |||

| Thickness of flexo plate & double-side tape | Photopolymer plate (2.38+0.38)mm (or according to customer requirements) | |||

| Suitable Ink | Water base ink or solvent ink. | |||

| Printing repeat length | 175mm-410mm | |||

| Suitable Material | PP WOVEN, PLSATIC FILM, PAPER(20-250g/cm²), NON-WOVEN | |||

| Machine Voltage | 380V/3phase /50HZ or according to customer requirements | |||

Video Introduction

Welcome to watch videos of our machines on YouTube, and if you like, please subscribe to our channel.

Machine features

1. The main motor adopts imported frequency converter with stepless speed regulation.

2. The unwinding and rewinding parts use magnetic powder brakes to adjust the substrate tension. Automatic tension controller adjustment.

3. The unwinding adopts hydraulic automatic loading, and the maximum unwinding diameter can reach 1200mm, which is suitable for paper materials.

4. The unwinding part is equipped with an automatic deviation correction system, so the material runs in a straight line without deviation.

5. A single scraper and ceramic anilox roller transfer ink, with long service life, wear resistance and corrosion resistance, which can reduce the number of replacements anilox rollers and improve printing efficiency.

6. The printing unit adopts 360-degree full circumferential plate adjustment, and the color registration accuracy reaches ±0.2mm.

7. Each group of printing units is equipped with a set of infrared drying devices, which can be replaced with UV drying devices.

8. The air shaft is used to clamp the substrate during unwinding and rewinding.

9. When the machine is stopped, the plate roller automatically detaches, and the motor drives the anilox roller to continue rotating to prevent the ink from drying out.

9. The maximum printing speed reaches 120 meters per minute, and the winding adopts surface curling friction. It is an ideal flexo printing machine for printing paper cups, food paper bags, and paper straws.

Printing sample

Packaging and Delivery