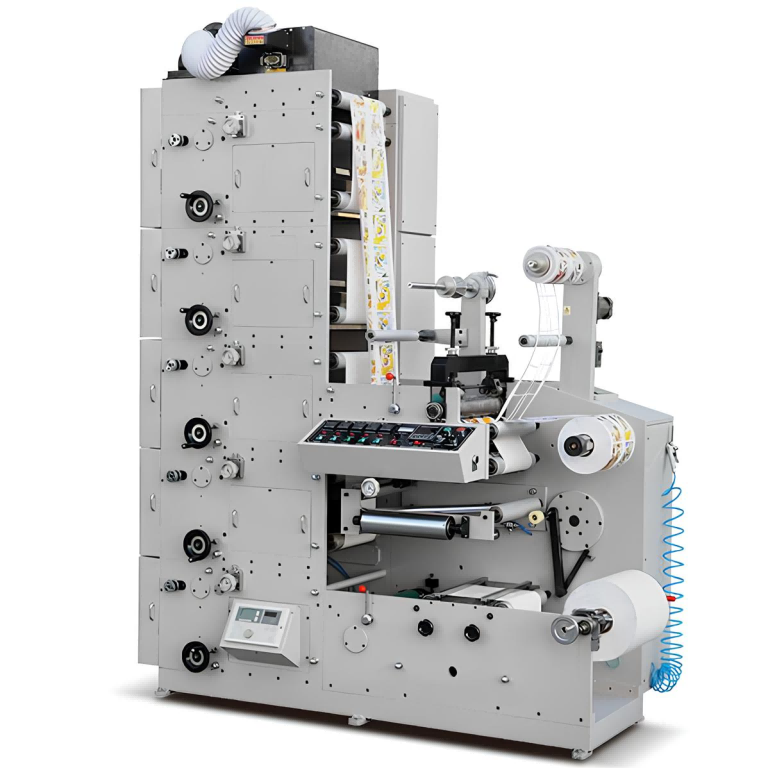

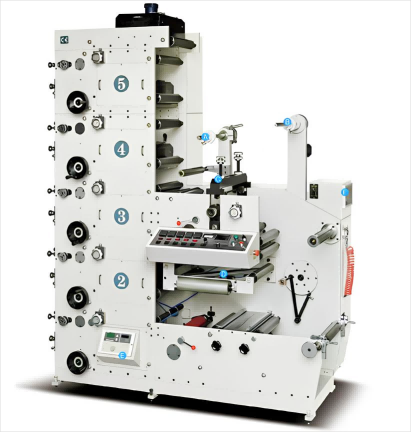

The 6-color label printing machine is a stack flexo printing machine with a maximum printing speed of 100 meters per minute. It can also complete printing, varnishing, laminating, slitting, die-cutting and other processes at one time. The whole machine adopts gear transmission. Its price is significantly lower than the unit-type label printing machine, and it can meet the trademark printing requirements of general quality requirements.

Parameter

| TECHNICAL SPECIFICATIONS | ||||

| Model | CYRY6-320 | CYRY6-350 | CYRY6-450 | CYRY6-650 |

| Max. Web Width | 330mm | 360mm | 460mm | 660mm |

| Max. Printing Width | 320mm | 350mm | 450mm | 650mm |

| Max. Machine Speed | 120m/min | |||

| Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | φ600mm | |||

| Machine Transmission Structure | Gear drive | |||

| Plate thickness & double side tape | Photopolymer plate 1.7mm or 1.14mm (or according to customer requirements) | |||

| Suitable Ink | Water base ink, solvent ink & UV ink. | |||

| Printing repeat length | 175mm-400mm | |||

| Range Of Substrates | BOPP, CPP, PET, PE, PAPER, Label Sticker | |||

| Electrical supply | Voltage 380V/3Phase/50HZ or according to customer requirements | |||

Video Introduction

Welcome to watch videos of our machines on YouTube, and if you like, please subscribe to our channel.

Machine Features

◊ Suitable for various high-end self-adhesive trademarks and film materials.

◊ The whole machine adopts imported frequency converter to control the speed, and the maximum printing speed reaches 100 meters per minute.

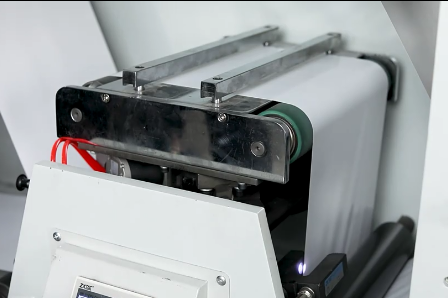

◊ Both unwinding and rewinding use a 3-inch air expansion shaft to clamp the material and automatically control the tension.

◊ The unwinding part is equipped with an auto web guide system to prevent the material from deflecting.

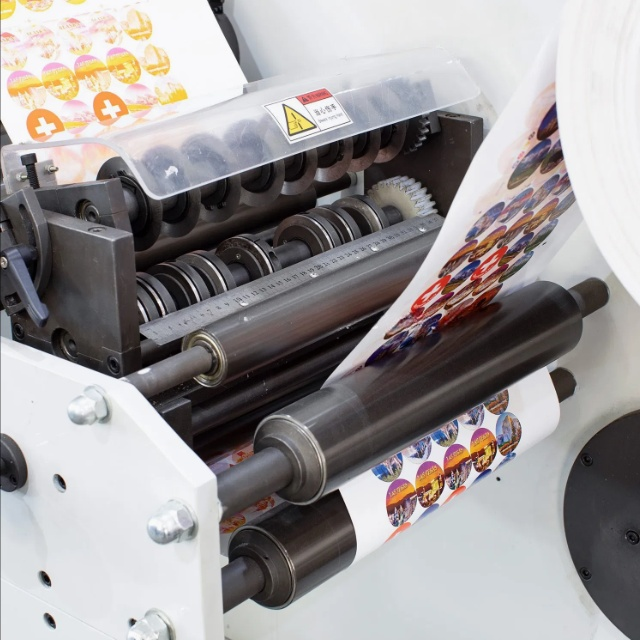

◊ Single scraper and ceramic anilox roller transfer ink, ensuring uniform ink volume. Ceramic rollers have a long service life, are corrosion-resistant and wear-resistant.

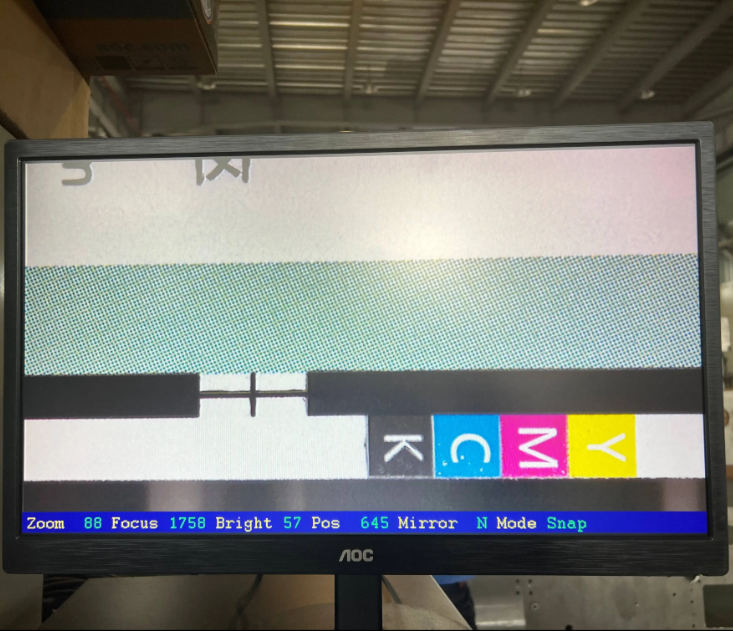

◊ Manual pressure adjustment,360-degree circumferential color registration adjustment, color registration accuracy reaches ±0.15mm

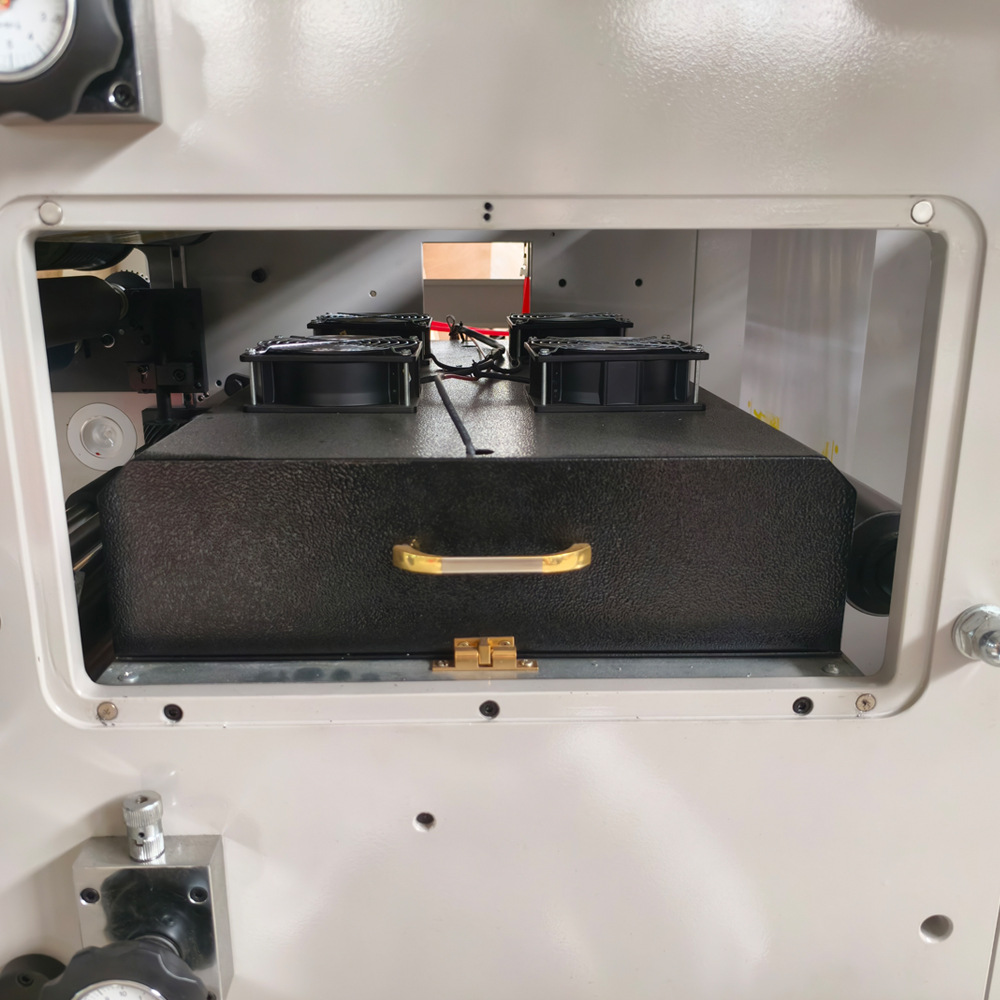

◊ Each printing unit has an independent infrared drying device, which can be replaced with a UV drying device.

◊ Die-cutting, slitting, glazing, laminating, and cross-cutting devices can be installed according to customer requirements.

◊ When printing heat-shrinkable materials, a water-cooling roller can be installed to prevent the material from deforming due to excessive temperature after drying.

◊ The machine is made of 60mm thickened iron wall panels and operates stably.

◊ Independent hydraulic unwinding can be selected according to customer requirements; the maximum unwinding diameter reaches 1000mm.

Machine Details

Printing Sample

Packaging and Delivery