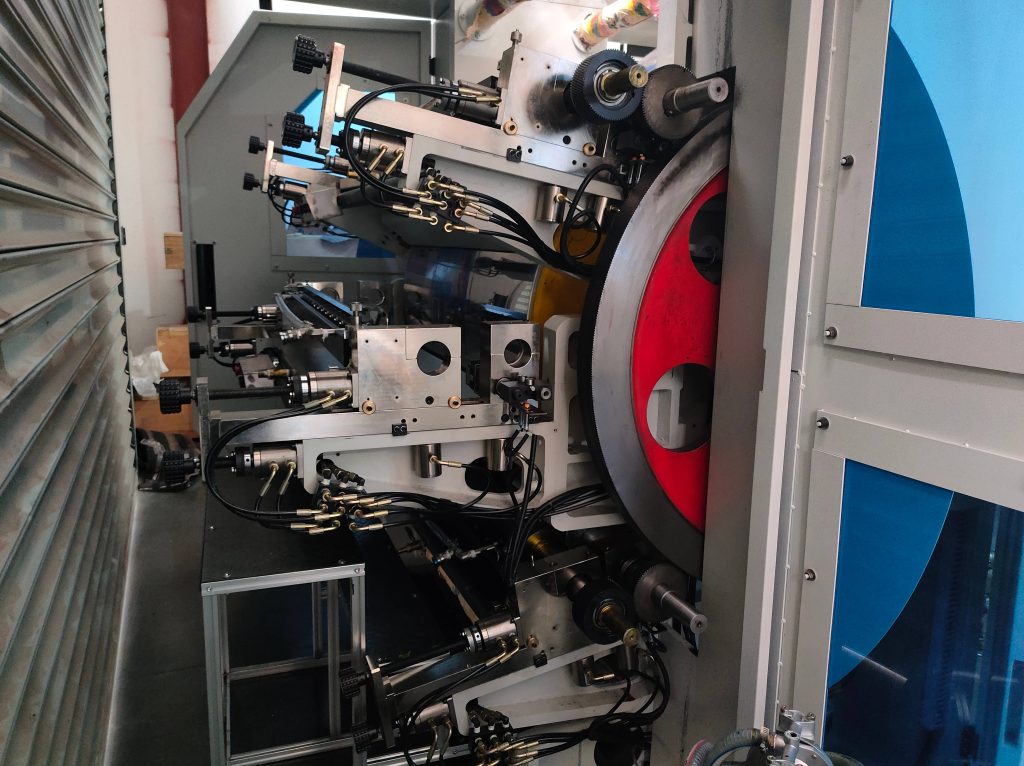

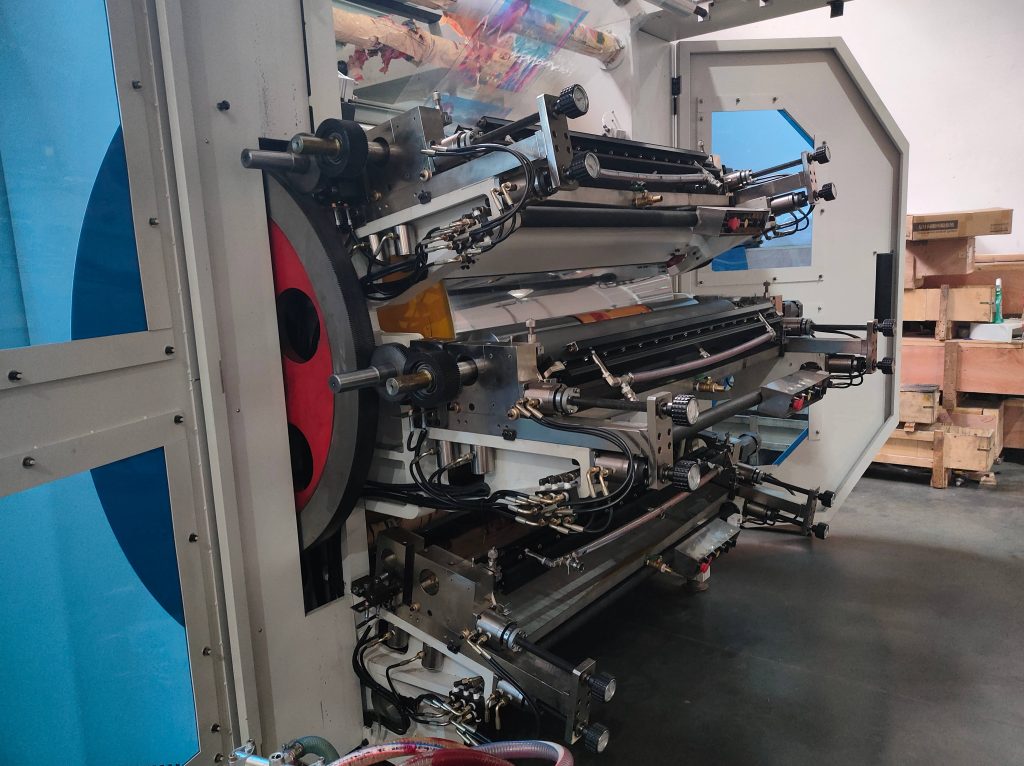

CI Flexographic Printing Machine, also known as the central impression flexographic press. All printing units of the CI flexographic press are arranged around a central drum for high-quality printing and registration accuracy. Our 6 color flexo printing machine max speed reach 200meter/min, it is suitable for printing deformable printing materials, such as PET, BOPP, PVC and other film materials.

| TECHNICAL SPECIFICATIONS | ||||

| Model | YTC-800 | YTC-1000 | YTC-1200 | YTC-1400 |

| Max. Material Width | 800mm | 1000mm | 1200mm | 1400mm |

| Max. Printing Width | 760mm | 960mm | 1160mm | 1360mm |

| Max. Machine Speed | 250m/min | |||

| Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | φ1000mm | |||

| Drive structure | Gear drive. | |||

| thickness of flexo plate | Photopolymer plate 2.38mm (or according to customer requirements) | |||

| Suitable Ink | Water based ink & solvent ink. | |||

| Printing repeat length | 350mm-900mm | |||

| Suitable material | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN | |||

| Machine voltage | Voltage 380V/3Phase /50 HZ (or according to customer requirements) | |||

Video Introduction

Welcome to watch videos of our machines on YouTube, and if you like, please subscribe to our channel.

Main characters

◊ A wide range of substrates, such as pet, Bopp, paper, non-woven, pp woven and so on.

◊ The printing material is tightly attached to the surface of the large central drum, and the tension is stable, especially when printing shrinkable films.

◊ Chamber doctor blade and ceramic anilox roller transfer ink, diaphragm pump circulate ink, ink volume is stable.

◊ The surface of the central impression drum is chrome-plated, with a diameter of up to 2 meters and constant temperature control.

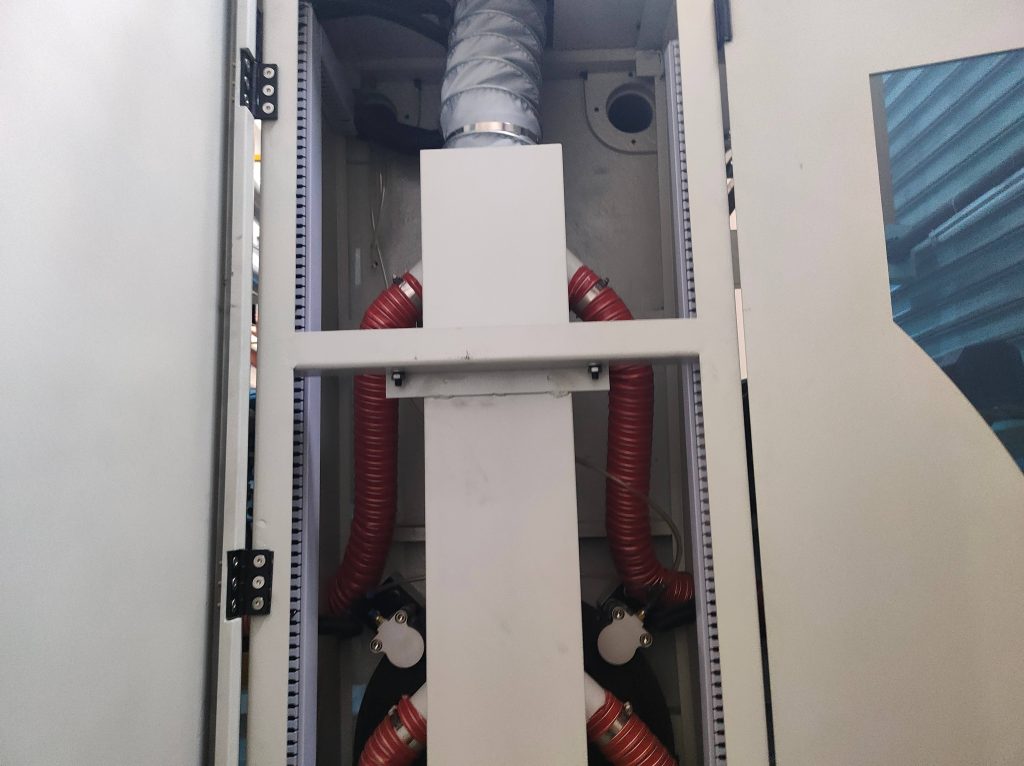

◊ When printing materials such as heat shrink film that require water cooling, a water-cooling device can be installed.

◊ Independent hot air electric heating drying unit, high efficiency and energy saving, optional steam or hot oil drying.

◊ The printing speed can reach up to 300 meters per minute. It adopts electric color registration and pressure adjustment, and the accuracy can reach ±0.12mm.

◊ Machine equipped with a video inspection camera to observe the printing quality in real time.

◊ Computerized automatic color registration systems, UV drying, turn bur, Non-stop roll change platform) can be installed according to customer needs to meet different production needs.

Printing Sample

Packaging and Delivery