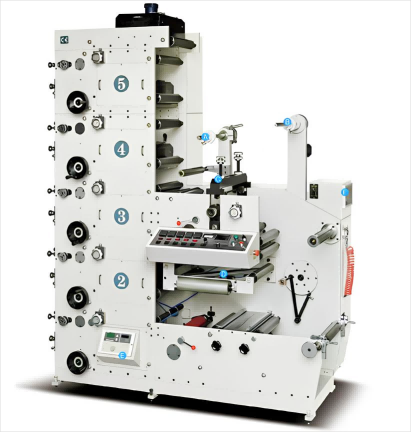

Each printing group of the 8-color inline flexo printing machine is directly driven by a servo motor. It adopts an automatic color registration system and an online quality inspection system. The maximum printing speed can reach 150 meters per minute. It can complete printing, glazing, laminating, slitting, die-cutting and other processes at one time. It is an ideal flexographic printing machine for high-end trademark printing and self-adhesive printing. It can be used in food labels, medical labels, cosmetic labels and other fields.

Parameter

| TECHNICAL SPECIFICATIONS | ||||

| Model | CYRY8-320 | CYRY8-350 | CYRY8-450 | CYRY8-650 |

| Max. Material Width | 330mm | 350mm | 450mm | 650mm |

| Max. Printing Width | 320mm | 350mm | 450mm | 650mm |

| Max. Machine Speed | 180m/min | |||

| Printing Speed | 150m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Machine Drive Structure | Servo drive | |||

| Plate thickness & double side tape | Photopolymer plate (1.7+2.38)mm (or according to customer requirements) | |||

| Suitable Ink | Water base ink or solvent ink | |||

| Printing repeat length | 175mm-610mm | |||

| Range Of Substrates | BOPP, CPP, PET, PVC, PAPER (20-150g/㎡) | |||

| Electrical supply | Voltage 380V/3Phase/50HZ or according to customer requirements | |||

Video Introduction

Welcome to watch videos of our machines on YouTube, and if you like, please subscribe to our channel.

Machine features

◊ Suitable for all kinds of high-grade self-adhesive trademarks and film materials.

◊ The whole machine adopts PLC control, which is simple to operate and easy to maintain.

◊ Both unwinding and rewinding use air expansion shafts to clamp the material and automatically control the tension.

◊ Each printing group is directly driven by imported servo motors, and the machine operates stably.

◊ A single scraper and ceramic anilox roller transfer ink, with uniform ink volume. The ceramic roller has a long service life and is corrosion-resistant and wear-resistant.

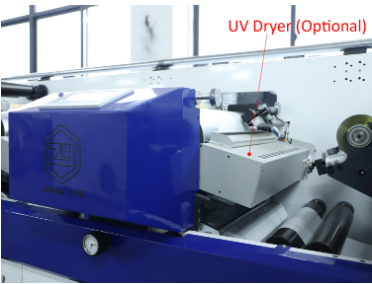

◊ Each group of printing units has an independent set of infrared drying devices, which can be replaced with UV drying devices.

◊ Die-cutting, slitting, glazing, laminating, and cross-cutting devices can be installed according to customer requirements.

◊ When printing heat-shrinkable materials, a water-cooled roller can be installed to prevent the material from deforming due to excessive temperature after drying.

◊ The machine is made of thickened 60mm iron wall panels and operates stably.

Machine Details

Printing Sample

Packaging and Delivey