With the rapid development of economy and the improvement of living standards, people pay more and more attention to the exquisiteness of packaging. The single-color corrugated carton's transportation and packaging functions of simply protecting products and facilitating storage and transportation are increasingly unable to meet the needs of sales. Therefore, colored corrugated carton packaging is gradually attracting customers' attention. At present, in order to solve the color printing needs of corrugated cartons, pre-printing processing methods have emerged in the printing and processing of corrugated cartons. Today we will introduce a printing machine suitable for pre-printing of corrugated boxes—Inline flexo printing machine. The pre-printing process refers to printing the face paper roll-to-roll before the production of corrugated cardboard. After printing, the web paper is collected into a roll, and then the printed roll paper is sent to the paper worker of the corrugated machine. Position, corrugated cardboard is processed, and then the predetermined color corrugated cardboard boxes are formed through subsequent processes, which is also face paper printing (roll paper)→corrugated cardboard processing → cross-cutting, die-cutting/grooving → box gluing/stacking.

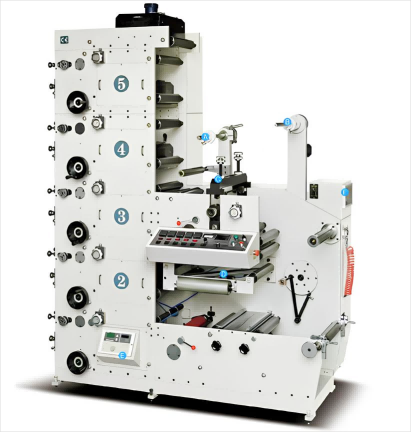

What is Inline flexo printing machine?

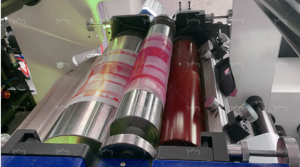

Flexo printing is a recognized green and environmentally friendly printing method in the world. It emits less when printing with ink and causes little environmental pollution, so it is often used in the food printing industry. Flexo printing mainly includes three main models:1. inline flexo printing machine 2. CI flexo press 3. stack flexo press. Among them, the wide web inline flexo printing machine is the ideal model for pre-printing corrugated cartons.

Structure of Inline flexo printing machine

Each printing unit is independent of each other and arranged in a straight line along the horizontal direction. Each printing unit is driven by a servo motor. The number of printing units can be determined according to the user's specific requirements. Up to twelve units can be achieved. 12 color printing. Equipped with an automatic color registration system, the color registration accuracy is high, and the printing quality is good.

Advantages and disadvantages

The inline flexo printing machine has a long material path when printing paper, which facilitates material drying. The speed can reach 250 meters per minute. It is equipped with an automatic color registration system and a monitoring system, and the printing effect is good. However, it occupies a large area, has high power and energy consumption, and has relatively high requirements for the site.