what is flexographic printing?

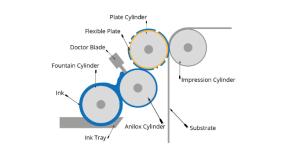

Flexographic printing uses a flexible printing plate to transfer ink through anilox rollers. It is a type of letterpress printing process, referred to as flexographic printing. The graphic part of the flexographic printing plate is raised. During printing, the anilox roller evenly coats a certain thickness of ink layer on the graphic part of the printing plate, and then transfers the ink layer of the graphic part under the pressure of the impression roller. to the surface of the substrate to form clear graphics and text. The inking mechanism of a flexographic printing press is usually a two-roller inking mechanism.

History of flexographic printing

In 1890 the first such patented press was built in Liverpool, England by Bibby, Baron and Sons. The water-based ink smeared easily, leading the device to be known as "Bibby's Folly". In the early 1900s, other European presses using rubber printing plates and aniline oil-based ink were developed. This led to the process being called "aniline printing". By the 1920s, most presses were made in Germany, where the process was called "gummidruck", or rubber printing. In modern-day Germany, the process continues to be called "gummidruck".

During the early part of the 20th century, the technique was used extensively in food packaging in the United States. However, in the 1940s, the Food and Drug Administration classified aniline dyes as unsuitable for food packaging and as a result, printing sales plummeted. Individual firms tried using new names for the process, such as "Lustro Printing" and "Transglo Printing" but met with limited success. Even after the Food and Drug Administration approved the aniline process in 1949 using new, safe inks, sales continued to decline as some food manufacturers still refused to consider aniline printing. Worried about the image of the industry, packaging representatives decided the process needed to be renamed. The greatest advances in flexographic printing have been in the area of photopolymer printing plates, including improvements to the plate material and the method of plate creation. Digital direct to plate systems have seen a good improvement in the industry recently. Companies like DuPont, Kodak, XSYS, and Esko have pioneered the latest technologies, with advances in fast washout and the latest screening technology. Laser-etched ceramic anilox rolls along with chambered ink systems, have also played a part in the improvement of print quality. Full-color picture printing is now possible, and some of the finer presses available today, in combination with a skilled operator, allow quality that rivals the lithographic process. One ongoing improvement has been the increasing ability to reproduce highlight tonal values, thereby providing a workaround for the very high dot gain associated with flexographic printing.

Application of Flexographic printing

Flexo has an advantage over lithography in that it can use a wider range of inks, water based rather than oil-based inks, and is good at printing on a variety of different materials like plastic, foil, acetate film, brown paper, and other materials used in packaging. Typical products printed using flexography include brown corrugated boxes, flexible packaging including retail and shopping bags, food and hygiene bags and sacks, milk and beverage cartons, flexible plastics, self-adhesive labels, paper cups and containers, envelopes and wallpaper. In recent years there has also been a move towards laminates, where two or more materials are bonded together to produce new material with different properties than either of the originals. A number of newspapers now eschew the more common offset lithography process in favour of flexo. Flexographic inks, like those used in gravure and unlike those used in lithography, generally have a low viscosity. This enables faster drying and, as a result, faster production, which results in lower costs.

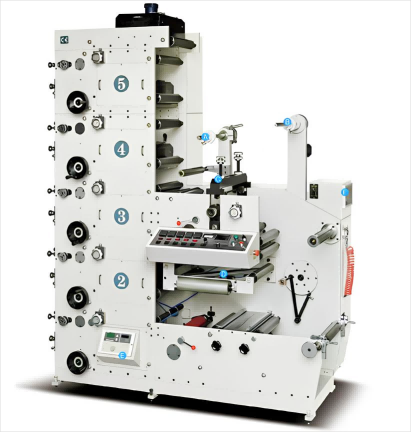

Printing press speeds of up to 750 meters per minute (2000 feet per minute) are achievable now with modern technology high-end printers. Flexo printing is widely used in the converting industry for printing plastic materials for packaging and other end uses. For maximum efficiency, the flexo presses produce large rolls of material that are then slit down to their finished size on slitting machines.